The A3XX aircraft produced by Airbus in Europe, the B77X aircraft produced by Boeing in the United States, the C919 aircraft produced by COMAC in China, and the CR929 aircraft produced by a Sino Russian joint venture all use many structural components made of titanium.

The development of China's fully independently developed C919 large passenger aircraft began in 2008. On November 2, 2015, the first prototype was taken offline and tested at Shanghai Commercial Aircraft Corporation of China. It made its first flight on May 5, 2017, underwent its first transition flight on November 10, and on December 17, the second C919 large aircraft successfully made its first flight at Shanghai Pudong Airport, marking a new stage of comprehensive test flight for domestic large aircraft. Although the materials used in the prototype are all foreign goods, they are mainly for the purpose of obtaining airworthiness certification. Since the second aircraft, the amount of domestic materials used has increased from batch to batch, and from year to year.

The main technical parameters of the C919 aircraft are shown in the table.

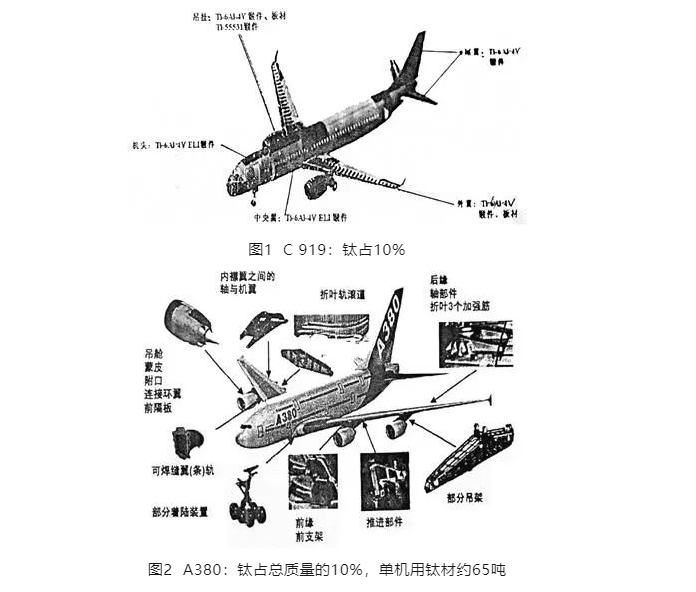

Titanium materials have been widely used in the manufacturing of large civil aircraft, with some key parts of the landing gear and wheels being forged with titanium alloy, and a small number of parts being forged with aluminum alloy. In the C919 aircraft, the net weight of titanium alloy components accounts for about 10% of the total net weight of the aircraft. It is the most commonly used titanium material in civil aircraft manufactured in China, and which components are made of titanium (see Figure 1): the nose is made of Ti-6Al-4VEVI forgings; Hanging, using Ti-6Al-4V alloy forgings, plates, and titanium alloy 55531 forgings; The tail wing is made of Ti-6Al-4V alloy forgings; The outer wing is made of Ti-6Al-4V alloy forgings and plates; The central wing is made of Ti-6Al-4V ELl alloy forgings; The landing gear system is made of Ti-6Al-4V alloy forgings.

Ti-6Al-4V (TC4, GB/T3620) is a medium strength (>900MPa) α+β Type A alloy, developed by the Watertown Arsenal in 1954, is widely used in the aerospace industry. Its semi-finished product production accounts for 55% -65% of the world's total titanium production, and is used to produce various aerospace forgings and plates. Due to its excellent comprehensive performance, moderate price, early formation, most in-depth research, longest usage time, and widest application fields, So this alloy has maintained strong vitality since its birth 67 years ago. The brand of this alloy is TC4 in China, Ti-6Al-4V in Timet, RMI 6Al4V in Active Metals, IMI318 in Titanium UK, BT6 in Russia, ST-AI40 in Sumitomo Metals, TA6V in France, and LT31 in Krupp Germany. TC4 alloy can be used in the annealed state for heat treatment strengthening, but its weldability is poor. The "ELI" in Ti-6Al-4V ELI indicates that the extremely low interstitial element titanium alloy is suitable for use at low temperatures α and α+β Titanium alloys, whose strength properties increase with decreasing temperature, and their toughness rarely decreases with decreasing temperature, can be used to manufacture low-temperature structural components. The oxygen content of low-temperature titanium alloys is very low, dropping from 0.2% oxygen to ≤ 0.12%, which can be used at extremely low temperatures (<77K). Typical alloys include Ti-5Al-2.5Sn (ELI) and Ti-6AI-4V (ELI). Ti-5Al-2.5Sn ELI is an American alloy that was introduced in the early 1960s and successfully replicated in China in the late 1970s, under the brand TA7 (Chinese military standard GJ B495). Ti-5Al-2.5Sn ELI alloy is particularly suitable for liquid fuel storage tanks operating at -255 ℃. Both types of titanium alloys can be adequately supplied by China Baoti Group.

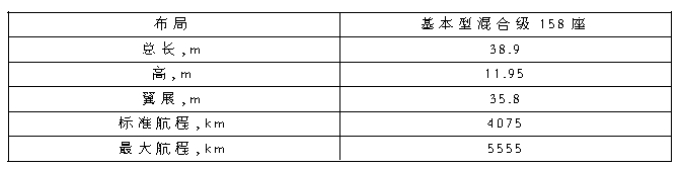

Airbus Europe's A380 large passenger aircraft is the world's largest wide body civilian aircraft and also the most commonly used in titanium materials. The net weight of titanium alloy components accounts for about 10% of the total net weight of the entire aircraft, and the amount of titanium used per aircraft is about 65 tons. The components made of titanium alloy mainly include (see Figure 2): the engine's nacelle, skin, attachment, connecting ring wing, front partition, shaft and wing between the inner flaps, folding blade track raceway, trailing edge, shaft components, and three reinforcing ribs of the folding blade. The engine's suspension, propulsion components, leading edge, front support, and some landing devices can be welded into wing (strip) rails.