Are you amazed, the forming process of Zhangqiu iron pot in "Bite of Tongue 3", hundreds of beats, making the red-hot iron become thin and strong. Did you know that the wing panels that make up the two wings of the large planes we often fly are also made with a similar process.

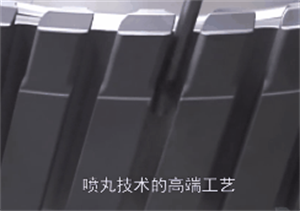

Of course, this high-end process called "shot peening technology" is much more complicated than the making of Zhangqiu iron pot. The common feature of the two is to strengthen the fatigue resistance and increase the strength through high-speed hitting. The difference is that the hammer becomes a small projectile with a diameter of no more than one centimeter, and the iron metal becomes an alloy raw material with better performance. The finished product is a large wing panel with extremely high toughness and strength requirements and a very complex shape.

Such a thick alloy raw material, under the high-frequency high-speed impact of hundreds of projectiles, becomes a hard, complex, and very thin skin, which is finally combined with the skeleton to form a complete wing. The plane flew at an altitude of 10,000 meters. Isn't this amazing?

So why do we use shot peening to process wing panels? First of all, we need to understand the special part of the aircraft wing panel.

Aircraft wing is a typical thin-walled structure, mainly composed of skin and skeleton. If you compare an airplane to a bird, the skin is the feathers that wrap around the skeleton of the airplane to create a streamlined outer surface. It must have a smooth shape in order to reduce drag; it must be very thin and light, reaching a dozen or even a few millimeters in order to effectively carry a load and lift the aircraft to fly higher; it must also be strong enough to withstand the aircraft at high altitudes. A variety of moving and twisting movements.

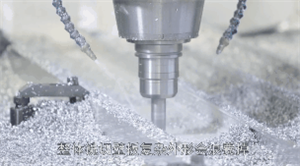

The traditional machining of wing panels usually adopts the method of CNC overall milling and appropriate mechanical bending method. The complex shape of the overall milling of the siding will waste a lot of materials, and the mechanical bending will easily affect the performance of the siding, and the quality control is very difficult. Today, domestic and foreign aviation manufacturing companies all use shot peening technology for wing panel processing.

First, the cost is low, no molds are required, raw materials are saved, and the site occupies less space.

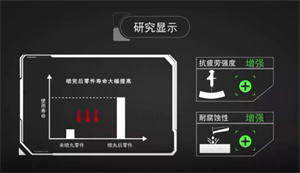

The second is high quality, and the continuous "beating" makes the surface of the parts more dense, just like adding a layer of protective film to the parts.

The third is the wide range of applications and how complex the shape is. Under the computer program, small projectiles can be accurately positioned and hit, effectively solving the problems of deformation of metal parts and deformation of welded parts.

The fatigue life of the parts processed by shot peening can be increased by dozens of times compared with the original, and the fatigue strength and corrosion resistance are greatly enhanced.

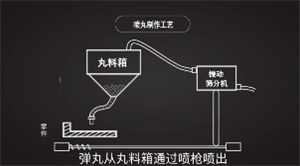

The medium of shot peening is usually called shot material, and there are many types, including cutting wire steel shot, carburized steel shot, hard cast steel shot, ceramic shot and so on. In the field of aircraft manufacturing, carburized steel shot and hard cast steel shot are generally used in shot peening, and hard cast steel shot and ceramic shot are mainly used in the shot peening process.

The machining process of shot peening is very interesting. In a special processing equipment, the projectiles are ejected from the shot box through the spray gun, hit the surface of the part at high speed, then pass through the recycling system, pass through the screening device to screen out the unqualified projectiles, and then return to the shot box for reuse.

In order to add stronger and lighter wings to domestic aircraft, the scientific and technical personnel of China's aviation industry are still working hard. More advanced technologies such as prestressed shot peening, ultrasonic shot peening, high-pressure water shot peening, and laser shock shot peening are bound to become available in the near future. play a greater role in the future.